- Office Hrs: 8:00 am to 5:00 pm

- 02-9972-0155

- 1800-611-332

Mobile Fume Filters

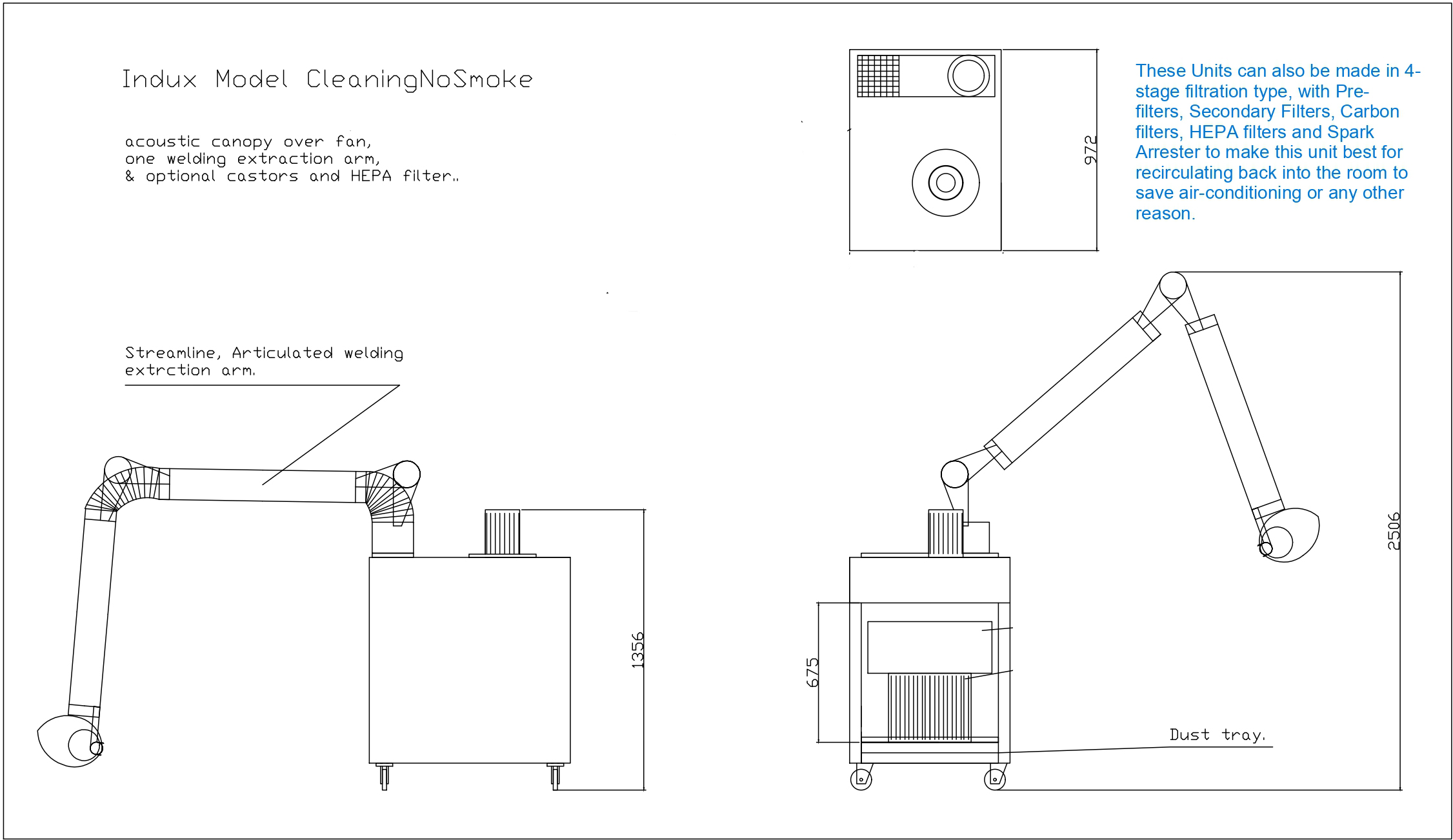

The “CleaningNoSmoke” fume extraction filtration system uses the latest filter technology to filter fumes and dust from welding, paints, glues, solvents, plastics, gases, and aerosols. The infinitely adjustable articulated fume arm sucks fumes into the hood. Air is then passed via a separation chamber, to allow dust to settle to the dust tray, air is then passed through three renewable filters. The high efficiency reverse curved extraction fan recycles to atmosphere the filtered air. The fan chamber is acoustically insulated to minimise fan breakout noise and duct transmitted impellor noise. The body of the “Cleaning NoSmoke” is manufactured from premium quality zinc seal mild steel panels, and powder-coat paint finish magnolia ripple, for good corrosion resistance.

The polluted air, aspirated through the end of the Universal No Smoke non supported articulated arm, is sent through the spark quenching set, “FIRECLEAN” (1) and the self-extinguishing prefilter, “PRECLEAN” (2). In the latter the dust with coarser granulometry is deposited. The air is then sent to the “SMOCLEAN” pocket filter (3) in glass fibre, with a large filter surface. The latter gathers the remaining solid particles.

The last filtration stage is made up of the activated carbons panel “ CARBOCLEAN” (4), after which the filtered air crosses the fan (5) and is expelled through the grill (6), after crossing the sound proofed baffle (7).

Technical Data

|

Cleaning No Smoke Model |

Max. Flow rate (m³/h-cfm) |

Filtration Efficiency |

Sound Level (dBA) |

Activated Carbon (Kg) LSB |

Power

(HP/Kw) |

|

1 Arm |

1500/885 |

99% |

71 |

17/35 |

2/1.5 |

|

2 Arms |

2300/1350 |

99% |

73 |

17/35 |

3/2.2 |